Operating Manual

Table of Contents

Product Description of the Machine

Intended Use

The C-Series pipe inspection system is designed exclusively for the inspection and condition assessment of pipelines and sewer systems. It is used for the visual inspection and documentation of pipe condition using specialized cameras and crawler vehicles.

Use is subject to the operating conditions and technical specifications described in this manual. Any use beyond these conditions or for purposes other than those described is considered improper and may result in damage to the system or hazards to the user.

The system must not be used in environments that:

- Contain potentially explosive atmospheres,

- Contain chemically aggressive substances,

- Exhibit excessively high or low temperatures outside the defined specifications,

- Are subject to high electrical or magnetic fields.

For safe and reliable operation, compliance with all safety and maintenance instructions provided in this manual is required.

Improper use

Any other or further use will be considered improper use.

In the event of improper use, the manufacturer’s liability under the Product Liability Act is void.

Predictable misuse

Predictable misuse can occur when operating the sewer inspection system.

Make sure you do not commit the following misuse.

- Grasping the moving cable.

- Reaching into the cable reel.

- Operating the cable reel with the covers removed.

- Reaching into the motorized components of the trolley.

- Reaching into the manually operated components of the trolley.

- Moving the trolley without lifting assistance.

- Lack of communication between assistant and inspector.

- Failure to follow the work sequence.

- Cable loops.

Special conditions

Always operate within the defined ambient temperature range (0°C to +40°C).

Adverse Conditions

- Do not operate during thunderstorms.

- Do not operate during heavy rain events.

- Do not operate without a backflow preventer.

- Do not operate outside the defined ambient temperature range.

- Do not operate outside the defined application area.

- Do not operate in uncleaned pipes.

- Do not operate in special profiles for which there are no suitable iPEK pipe adapters.

- Do not operate in pressurized pipes.

- Do not operate in pipes with a steep incline.

- Do not operate near high-voltage installations.

- Do not operate in direct sunlight.

Security

Read the safety instructions carefully and follow them. They serve your own safety, the safety of employees, and the prevention of damage to your equipment.

System description

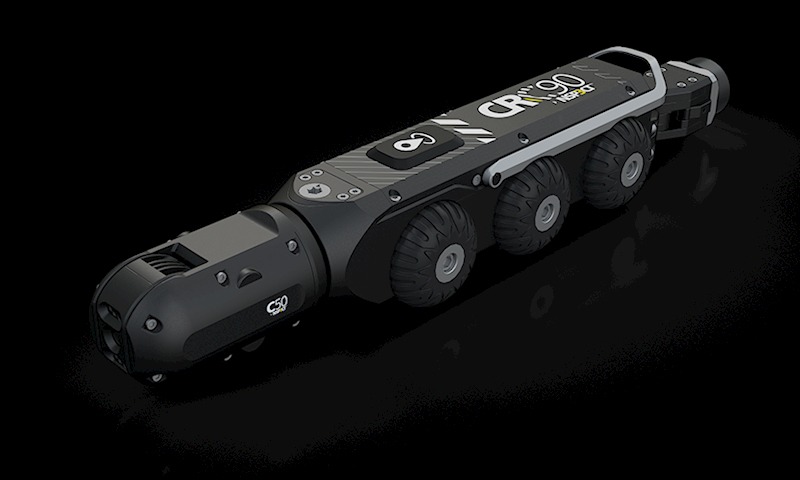

The C-Series Sewer Inspection System is a state-of-the-art, modular inspection system for verifying and documenting the condition of pipelines and sewer systems. It combines a powerful control and operating unit with high-resolution camera technology and a robust crawler system.

The system consists of the following main components:

- Control Unit – For operating and controlling all system functions.

- Crawler – A powered tracked vehicle for movement within the pipelines.

- Camera System – High-resolution pan and zoom camera for detailed inspections.

- Cable Drum – Automatic cable routing for flexible use in various pipe diameters.

Thanks to its modular design, the system can be adapted to different operating conditions and enables precise and efficient sewer inspection.

Technical Data

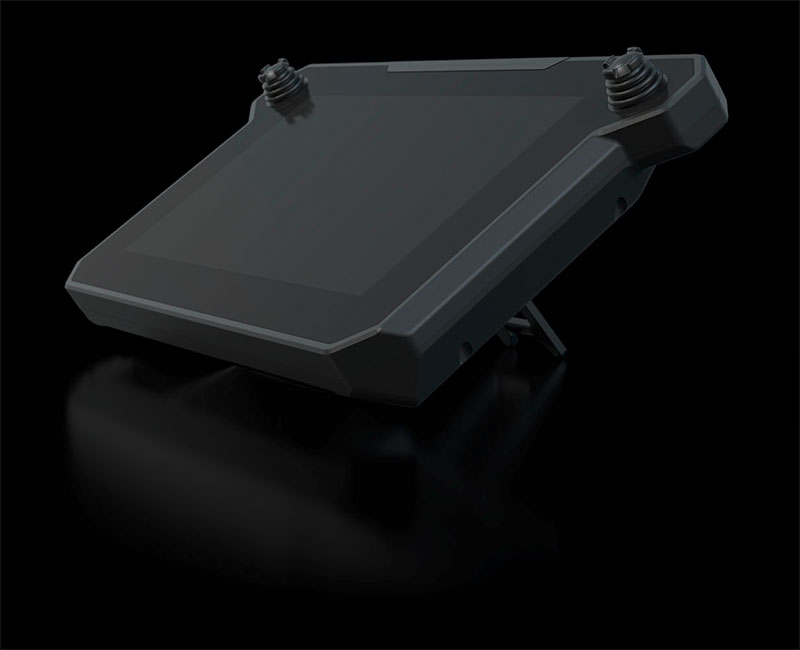

HMX

| Display type | TFT |

| Aspect ratio | 16:9 |

| Screen size | 11.6″ |

| Screen resolution | 1920 X 1080 px |

| Screen brightness | 1000 cd/m³ |

| Viewing angle | 160°/160° |

| Interfaces | WiFi, Bluetooth, USB-C, USB-A, HDMI, Ethernet |

| Memory (RAM) | 16 GB |

| Storage (internal) | 1 TB |

| Power supply | 24 V DC |

| Protection class | IP54 |

| Operating temperature range | 0° to 40°C |

| Storage temperature range | -20° to 60°C |

| Material | ABS, aluminum |

| Dimensions (LxWxH) | 386mm X 213mm X 80mm |

| Weight | Only 1.5 kg |

| Video format | mp4 |

| Special features | Two precise joysticks |

Technical Data

DRC100

| Drive | Motorized |

| Cable length | 100 m |

| Meter counter | Integrated (high-precision) |

| Voltage | 110 to 240 V AC |

| Mains frequency | 50/60 Hz |

| Protection rating | IP54 (dust- and splash-water protected) |

| Operating temperature range | 0° to 40°C |

| Storage temperature range | -20° to 60°C |

| Dimensions (LxWxH) | 340 X 401 X 440 mm |

| Weight incl. cable | 26.7 kg |

Technical Data

DRC200

| Drive | Manual/hand-operated |

| Cable length | 200 m |

| Meter counter | Integrated (high-precision) |

| Voltage | 110 to 240 V AC |

| Mains frequency | 50/60 Hz |

| Protection rating | IP54 (dust- and splash-water protected) |

| Operating temperature range | 0° to 40°C |

| Storage temperature range | -20° to 60°C |

| Dimensions (LxWxH) | 492 X 261 X 408 mm |

| Weight incl. cable | 24 kg |

Technical Data

DRC300

| Drive | Motor-driven |

| Cable length | 300 m |

| Meter counter | Integrated (high-precision) |

| Voltage | 110 to 240 V AC |

| Mains frequency | 50/60 Hz |

| Protection rating | IP54 (dust- and splash-water protected) |

| Operating temperature range | 0° to 40°C |

| Storage temperature range | -20° to 60°C |

| Dimensions (LxWxH) | 707 X 372 X 575 mm |

| Weight incl. cable | 70.5 kg |

| Special feature | Touch control display |

Technical Data

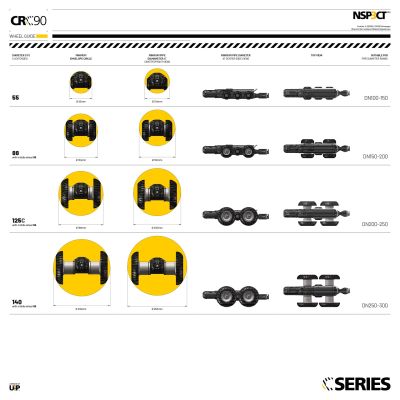

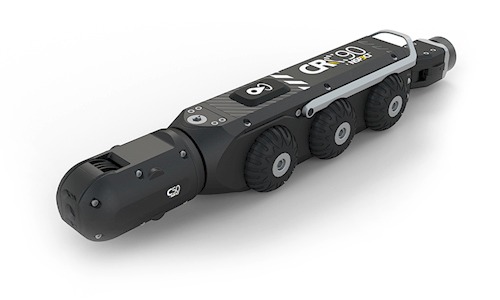

CRC90

| Drive | 6-wheel drive |

| Steerable | Yes |

| Nominal pipe sizes | DN100 – DN250 |

| Rear-view camera resolution | Full HD (1920 X1080 px) |

| Locator frequency | 512 Hz, 640 Hz, 33 kHz |

| Power supply | Via Cable Drum |

| Protection class | IP68 |

| Pressure-tight up to | 1 bar |

| Material | SUS 304 |

| Dimensions (LxWxH) | 430 X 106 X 99 mm |

| Weight incl. connector | 10.5 kg |

| Operating temperature range | 0 °C – 40 °C |

| Storage temperature range | -20 °C – 60 °C |

Technical Data

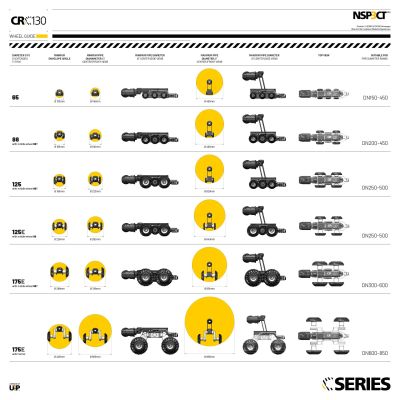

CRC130

| Drive | 6-wheel drive |

| Steerable | Yes |

| Nominal pipe sizes | DN150 – DN1000 |

| Rear-view camera resolution | Full HD (1920 X1080 px) |

| Locator frequency | 512 Hz, 640 Hz, 33 kHz |

| Power supply | Via Cable Drum |

| Protection class | IP68 |

| Pressure-tight up to | 1 bar |

| Material | SUS 304 |

| Dimensions (LxWxH) | 430 X 106 X 99 mm |

| Weight incl. connector | 10.5 kg |

| Operating temperature range | 0 °C – 40 °C |

| Storage temperature range | -20 °C – 60 °C |

Technical Data

C50

| Nominal pipe sizes | DN100 – DN300 |

| Crawler operation | CRC90, CRC130 |

| Pressure-tight up to | 1 bar |

| Tilt range | -135° – 135° |

| Rotation range | Endless |

| Field of view |

D:79.8° H:67.8° V:53.1° |

| Focus | 3.5 cm |

| Optical zoom | – |

| Digital zoom | 4X |

| Resolution | Full HD (1920 X1080 px) |

| Light sensitivity | 0.001 Lux @F1.8, AGC ON |

| Laser pointer | Yes |

| Laser spacing | 24 mm |

| Pressure sensor | 0.3 bar – 2.6 bar |

| Protection class | IP68 |

| Material | AL 6061, SUS 304, Sapphire glass |

| Dimensions (LxWxH) | Φ 58mm X 97mm |

| Weight | 0.6 kg |

| Operating temperature range | 0 °C – 40 °C |

| Storage temperature range | -20 °C – 60 °C |

CAUTION!

Technical Data

C90

| Nominal pipe sizes | DN100 – DN1000 |

| Crawler operation | CRC90, CRC130 |

| Pressure-tight up to | 1 bar |

| Tilt range | -135° – 135° |

| Rotation range | Endless |

| Field of view |

Zoom 1x: D:67.1° H:59.16° V:29.58° Zoom 10x: D:7.7° H:6.76° V:3.86° |

| Focus | 5 – 50 cm |

| Optical zoom | 10X |

| Digital zoom | 16X |

| Resolution | Full HD (1920 X1080 px) |

| Light sensitivity | 0.005 Lux |

| Laser pointer | Yes |

| Laser spacing | 65 mm |

| Pressure sensor | 0.3 bar – 2.6 bar |

| Protection class | IP68 |

| Material | AL 6061, SUS 304, Sapphire glass |

| Dimensions (LxWxH) | Φ 92mm X 168mm |

| Weight | 1.6 kg |

| Operating temperature range | 0 °C – 40 °C |

| Storage temperature range | -20 °C – 60 °C |

CAUTION!

Overview of the C-Series

Overall system

Main Components

- Crawler: A robust, remotely controlled vehicle for use in pipes and ducts.

- Camera Unit: High-resolution inspection cameras, mountable directly on the crawler.

- Control Panel / Controller: Control unit for navigating the crawler, live image transmission, and documentation.

- Cable Reel: Supplies the system with power and transmits data – automatic cable extension and retraction.

Extensions and Accessories

- Rubberized Wheels for different surfaces

- Drag rollers: For optimized cable routing and reduced resistance.

- Shaft accessories: Drainage devices, protective brackets, and guide rails for safe handling in shafts.

Areas of application

The system is suitable for inspections in pipelines from DN 100 to DN 900, depending on the wheel and accessory configuration. It can be adapted for various materials such as concrete, plastic, or steel and can be used in both dry and flooded pipes.

Accesories

Wheels for various applications

The C-Series Crawler system offers a selection of wheels for different operating conditions. The most important wheel types include:

- Standard wheels: These wheels are suitable for general use and provide a balanced combination of traction and durability.

Wheel Sizes and Specifications

Mechanical Extensions

In addition to the wheels, various mechanical extensions are available:

Riser: Extends the operating range of the carriage for larger diameters.

Electrical Extensions

Pulleys

Pulling pulleys are essential for efficiently and safely guiding the cable of the trolley system. They reduce resistance and ensure optimized cable routing in various application scenarios.

Available Pulleys:

- Standard Pulley: For easy cable routing, suitable for small to medium-sized shafts.

- Shaft Pulley with Height Adjustment: Allows the cable routing to be adapted to different shaft depths.

Lowering Devices and Adapters

Lowering Device: Allows the trolley to be safely lowered into the shaft using a hook.

Maintenance and Spare Parts

To ensure a long service life for the trolley system, various spare parts are available:

- Screw sets: For mounting and maintaining the wheels.

- O-rings and seals: To maintain the system’s watertightness.

- Lubricants: For optimal maintenance of the moving components.

Commisioning

- Check all components for visible damage and completeness.

- Ensure the system is placed on a stable and secure work surface.

- Read the safety instructions in the manual before operating the system.

- Cart: Connect the cart to the camera system interface. Ensure the connector is locked in place.

- Camera System: Mount the camera unit on the cart and secure the connection.

- Cable Reel: Properly connect the control panel to the cable reel. Connect the cable reel to the power supply and start the system.

- Switch on the cable reel and wait until the system has booted up.

- Check the camera functions (zoom, pan, lighting).

- Test the mobility of the trolley in a safe environment.

- Check the data transmission between the camera, trolley, and control unit.

- Check the pressure of the connected components.

- Ensure that all system components are functioning correctly.

- Adjust the camera settings and controls to the inspection conditions. Select the appropriate wheel set for the diameter and condition of the pipe being inspected.

- Begin the sewer inspection according to the established procedures.

Operation/User Interface

1. Starting the Software

- Connect the control unit to the system.

- Switch on the control unit and start the HMX software.

- Check the connection status of all components in the main menu.

2. Main Menu and Controls

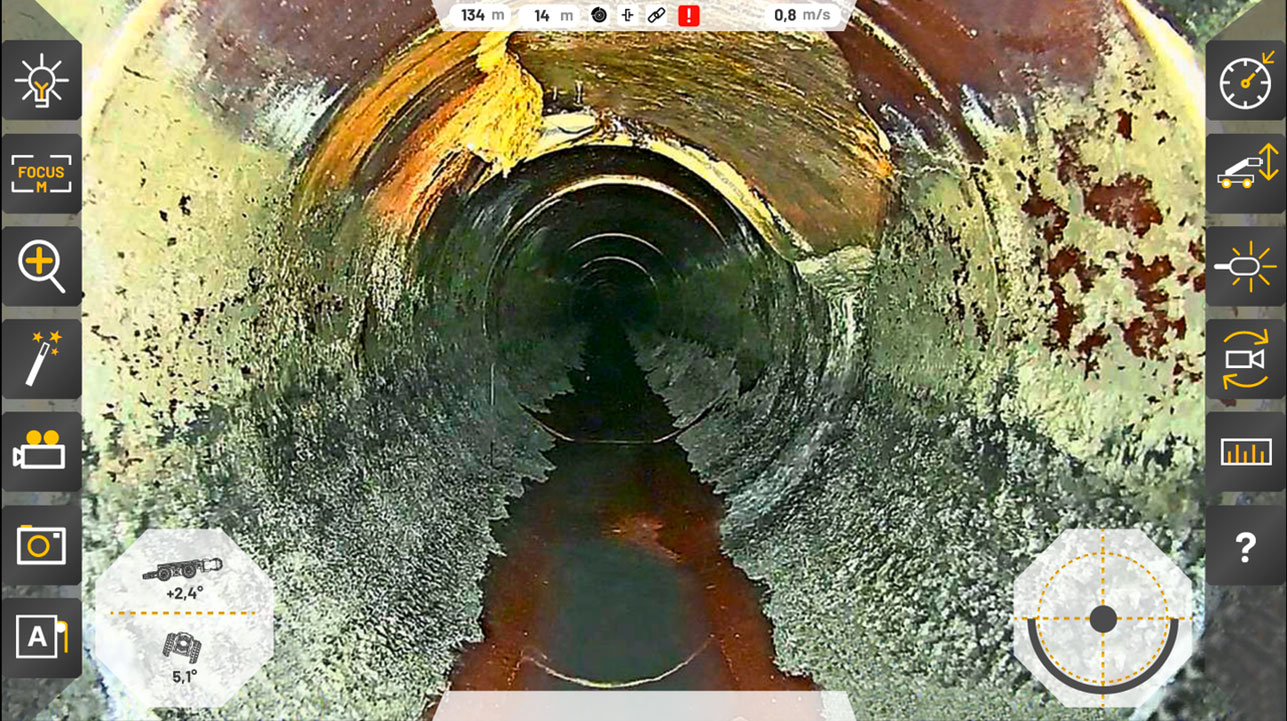

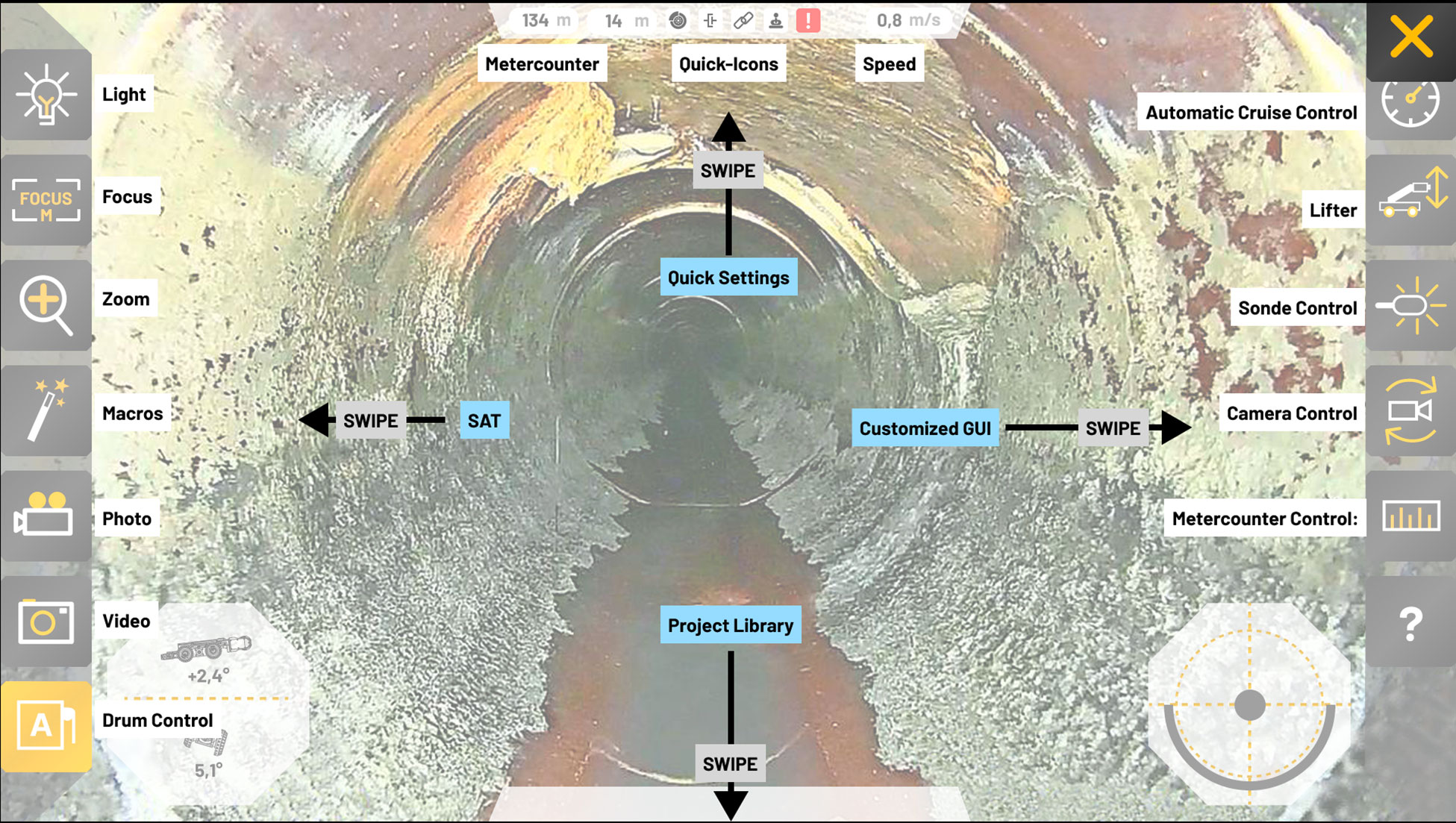

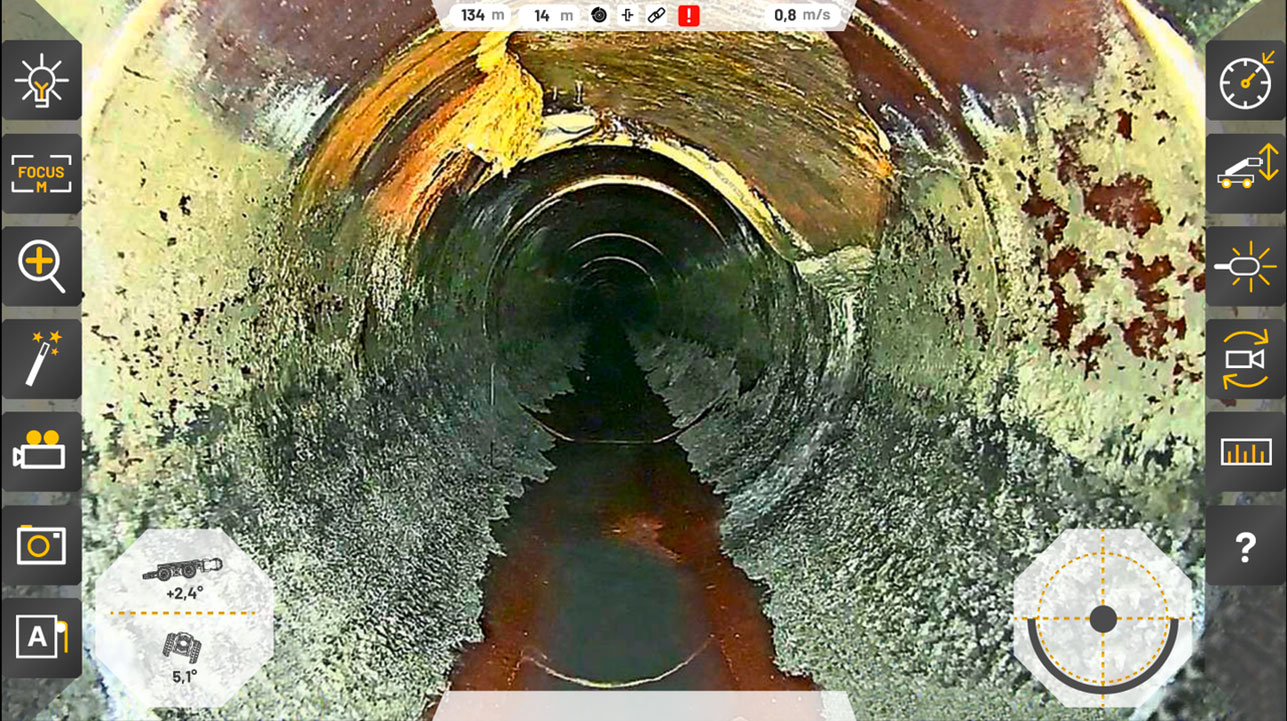

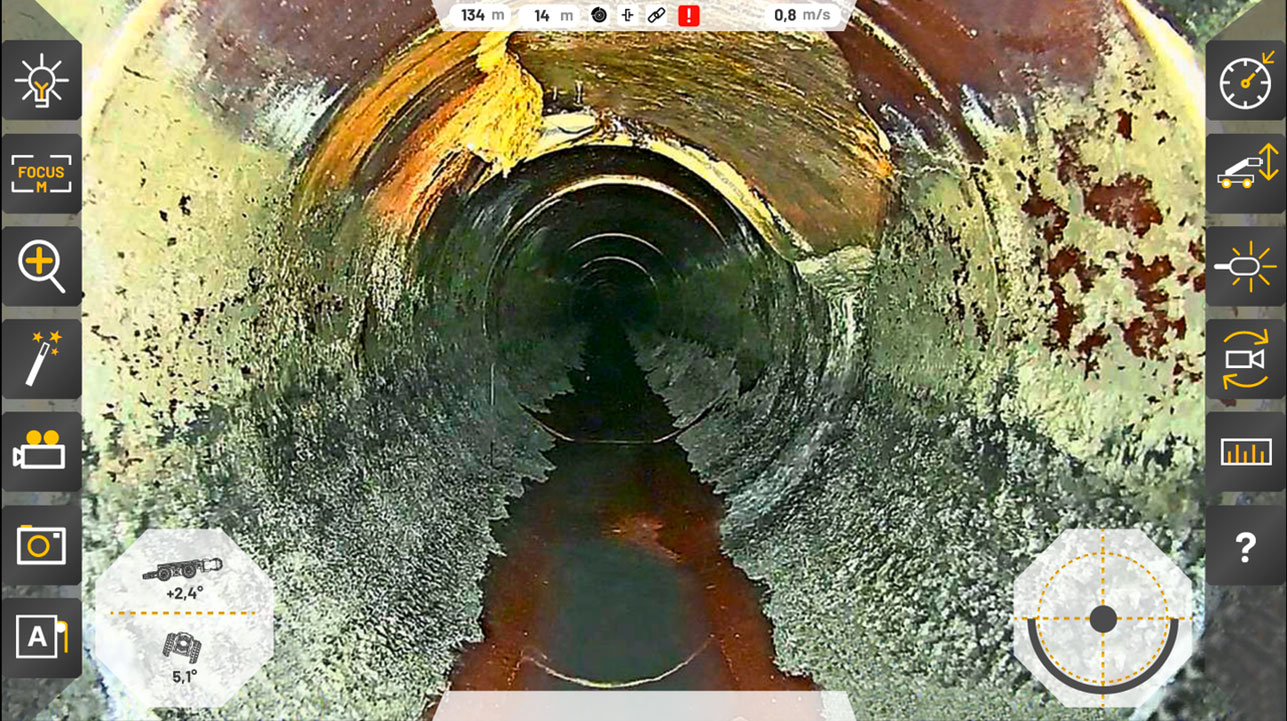

After startup, the main screen is the central workspace of the HMX system. The user manual shows only a sample version of the software; this may change due to its customization options, but the information and functions remain unaffected.

It displays the current video stream from the inspection system and serves as the main control environment for the operator.

3. Function Keys

- Adjust lighting

- Focus

- Adjust zoom

- Macros

- Take photo

- Start video recording

- Control cable drum

- Automatic speed control

- Lifter

- Control locating

- Camera Head Selection

- Meter control

- Show help

The current live image, possibly with data overlays, is always displayed in the background. The status bar at the top displays, among other things, the current meter reading, quick icons, and speed.

Overview of the Function Keys

Meterzähler-Anzeige

Zeigt die aktuelle Fahrdistanz vom Meterzähler an

Lighting Control

Pressing the button opens sliders for stepless adjustment of the lighting intensity.

Focus

The focus button displays A (Auto) or M (Manual) to indicate whether autofocus is currently active.

Pressing the button opens the corresponding controls: + and – for manually adjusting the focus, and the A/M button for switching between autofocus and manual mode.

The mode switch is only available if the connected camera supports this function.

If the main view displays an image from a camera with fixed focus, the focus button must be disabled (grayed out) or hidden.

Zoom

Opens the corresponding controls: the + and – buttons for adjusting the zoom level and a slider that displays the current zoom position.

All sliders must apply value changes immediately upon movement, not only after being released.

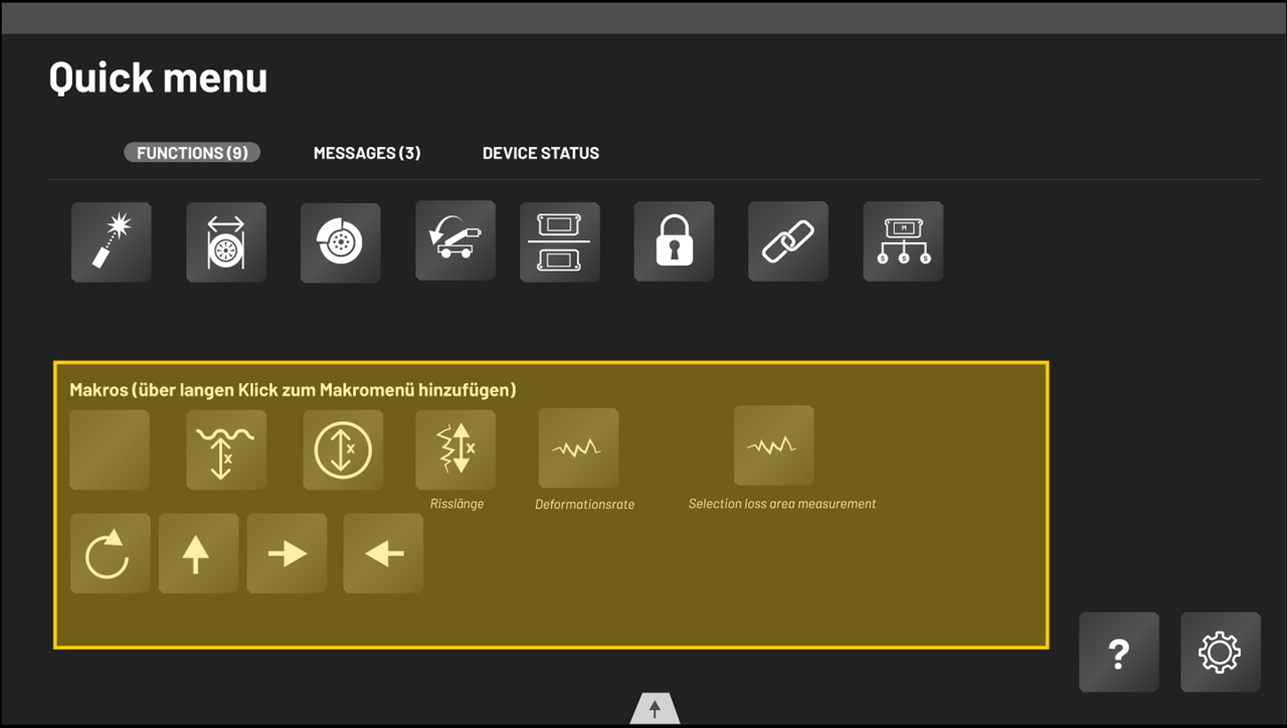

Macros

Opens the favorites macro menu, which provides quick access to your most frequently used macros.

Macros are added to this list by long-pressing a macro in the macro menu.

Once added, they will automatically appear under the magic wand icon on the main interface.

A maximum of five macros can be saved as favorites at one time.

From this menu, any macro can be launched instantly with a single tap.

Video Capture

Pressing this button starts video recording.

- The timecode begins.

- The recording icon changes to “Pause.”

- Message appears –> Stop recording. Are you sure? Yes/No

- Yes: Ends the current recording.

- The video recording is completed and saved.

Screenshots

Image Capture

Press the image capture button Creates a photo of the current camera image without menu navigation or bars.

Cable Drum Control

Indicates whether the drum is operating in automatic or manual mode and opens the corresponding controls.

All displayed controls depend on the connected drum type:

Cruise Control

Activates the cruise control function.

Once activated, the crawler accelerates to the desired speed using the joystick. After releasing the joystick, the crawler automatically maintains its current speed.

When the joystick returns to the neutral position and is moved again, the crawler stops. Moving the joystick forward or backward again accelerates the crawler and saves the new speed.

Pressing the cruise control button stops the crawler and deactivates the cruise control function.

Lifter Control

The lifter control allows the user to adjust the vertical position of the crawler’s lifting mechanism. This function raises or lowers the camera head to achieve optimal alignment for inspection inside the pipe.

Info: The displayed height value indicates the distance between the wheel axis (center of the crawler wheels) and the camera axis (center of the camera head).

Location

Short press: Turns the location tracking function on or off using the currently stored frequency.

When the function is active, the corresponding button (e.g., 512, 640, 33k) is highlighted in yellow and displays the selected frequency (see example → 512). When the function is inactive, the button returns to its default gray state.

Long press: Opens the frequency selection menu, where the user can select a different transmission frequency.

After selecting a new frequency, the transmitter is immediately activated with this setting.

Camera Head Selection

Meter Counter

Help Key

Lighting Control

Pressing the button opens sliders for stepless adjustment of the lighting intensity.

Focus

Focus Symbol

The focus button displays A (Auto) or M (Manual) to indicate whether autofocus is currently active.

Pressing the button opens the corresponding controls: + and – for manually adjusting the focus, and the A/M button for switching between autofocus and manual mode.

The mode switch is only available if the connected camera supports this function.

If the main view displays an image from a camera with fixed focus, the focus button must be disabled (grayed out) or hidden.

Zoom

Magnifying Glass Symbol

Opens the corresponding controls: the + and – buttons for adjusting the zoom level and a slider that displays the current zoom position.

All sliders must apply value changes immediately upon movement, not only after being released.

Macros

Magic Wand Symbol

Opens the favorites macro menu, which provides quick access to your most frequently used macros.

Macros are added to this list by long-pressing a macro in the macro menu.

Once added, they will automatically appear under the magic wand icon on the main interface.

A maximum of five macros can be saved as favorites at one time.

From this menu, any macro can be launched instantly with a single tap.

Video Capture

Video Camera Symbol

Pressing this button starts video recording.

- The timecode begins.

- The recording icon changes to “Pause.”

- Message appears –> Stop recording. Are you sure? Yes/No

- Yes: Ends the current recording.

- The video recording is completed and saved.

Screenshot/Image Capture

Photo Camera Symbol

Press the image capture button Creates a photo of the current camera image without menu navigation or bars.

Cable Drum Control

Cable Drum Symbol

Indicates whether the drum is operating in automatic or manual mode and opens the corresponding controls.

All displayed controls depend on the connected drum type:

Cruise control

Speedometer Symbol

Activates the Cruise Control function.

Once activated, the crawler accelerates to the desired speed using the joystick. After releasing the joystick, the crawler automatically maintains its current speed.

When the joystick returns to the neutral position and is moved again, the crawler stops. Moving the joystick forward or backward again accelerates the crawler and saves the new speed.

Pressing the cruise control button stops the crawler and deactivates the cruise control function.

Lifter Control

Lifter Symbol

The lifter control allows the user to adjust the vertical position of the crawler’s lifting mechanism. This function raises or lowers the camera head to achieve optimal alignment for inspection inside the pipe.

Info: The displayed height value indicates the distance between the wheel axis (center of the crawler wheels) and the camera axis (center of the camera head).

Location

Sonde Symbol

Short press: Turns the location tracking function on or off using the currently stored frequency.

When the function is active, the corresponding button (e.g., 512, 640, 33k) is highlighted in yellow and displays the selected frequency (see example → 512). When the function is inactive, the button returns to its default gray state.

Long press: Opens the frequency selection menu, where the user can select a different transmission frequency.

After selecting a new frequency, the transmitter is immediately activated with this setting.

Camera Head Selection

Meter Counter

Ruler Symbol

Help

Question Mark Symbol

Status Bar

Absolute

Cable Length

Displays the absolute cable length.

Relative

cable length

Connection Status

Crawler

Displays the status of the electronic coupling in the Crawler.

Connection Status

Cable Drum

Displays the status of the coupling in the cable drum.

Link

Warning Symbol

Indicates that one or more alerts are active. Alerts can be viewed in the “Notifications” section of the quick menu.

The icon is hidden when there are no alerts.

Speed

Absolute Cable Length

Relative Cable Length

Connection Status Crawler

Displays the status of the electronic coupling in the Crawler.

Connection Status Cable Drum

Displays the status of the coupling in the cable drum.

Link

Chain Symbol

Warning Symbol

Indicates that one or more alerts are active. Alerts can be viewed in the “Notifications” section of the quick menu.

The icon is hidden when there are no alerts.

Speed

Quick Menu

The quick menu provides direct access to frequently used commands and functions. It is designed so that the operator can trigger important actions quickly without having to navigate through deeper menus. When a function is activated in the quick menu, the corresponding icon turns yellow to indicate that the function is currently active.

- Direct functions (e.g., laser measurement) are executed immediately after selection – in this case, the laser is switched on.

- Input functions (e.g., wheel diameter) open an input dialog where the user can enter or adjust specific parameters.

In addition, status messages (separate menu) and the status of each individual component are displayed.

Messages – Displays current system warnings and error messages.

Device status – Displays a detailed overview of all connected devices. Each device reports various operating parameters.

The settings menu can be accessed via Settings:

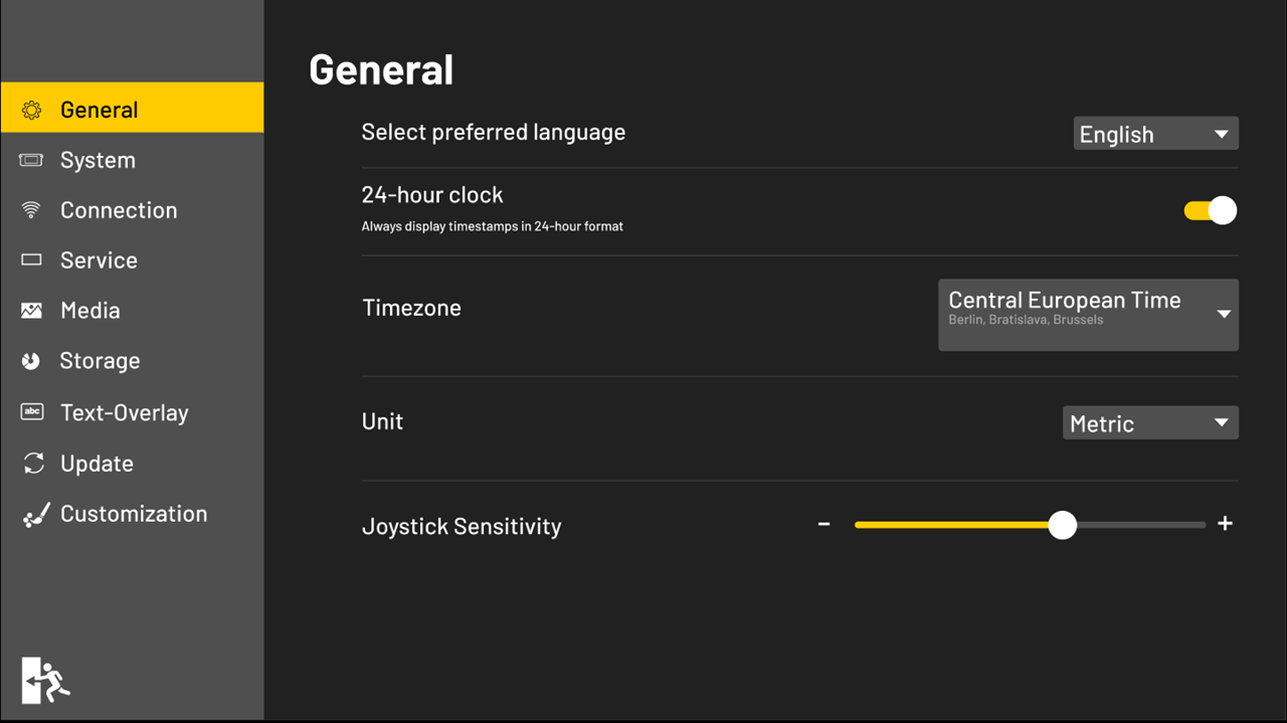

Settings Menu

The “Settings” menu provides access to all configuration options of the HMX system. Here, the user can adjust general settings, system behavior, service tools, and overlay functions, allowing the control unit to be adapted to different environments and inspection requirements. The “Settings” menu can be accessed via the quick menu.

- The main settings categories are listed on the left side.

- The currently active category is highlighted in yellow.

- Selecting a category displays the corresponding settings on the right side.

- When opening the settings menu, the first category “General” is preselected and highlighted in yellow as the active view.

- Use the button in the bottom left to exit the settings menu and return to the previous (quick menu).

- All settings are permanent and remain saved even after a restart.

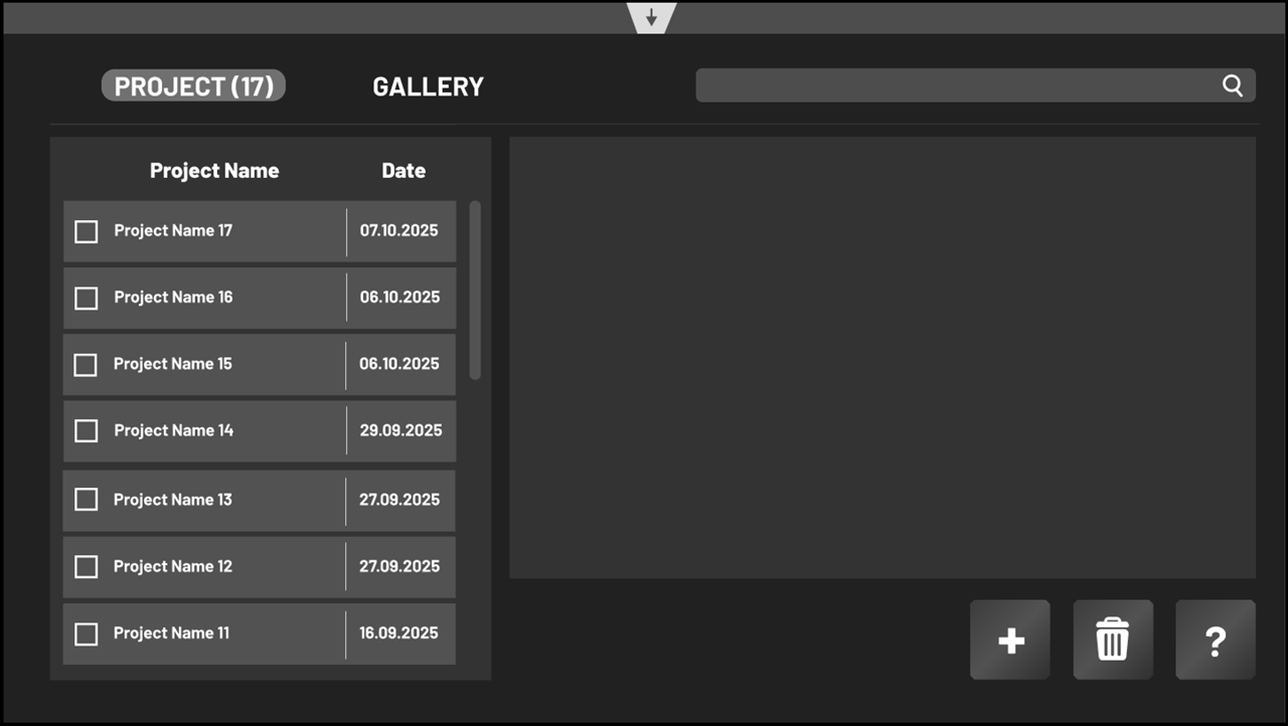

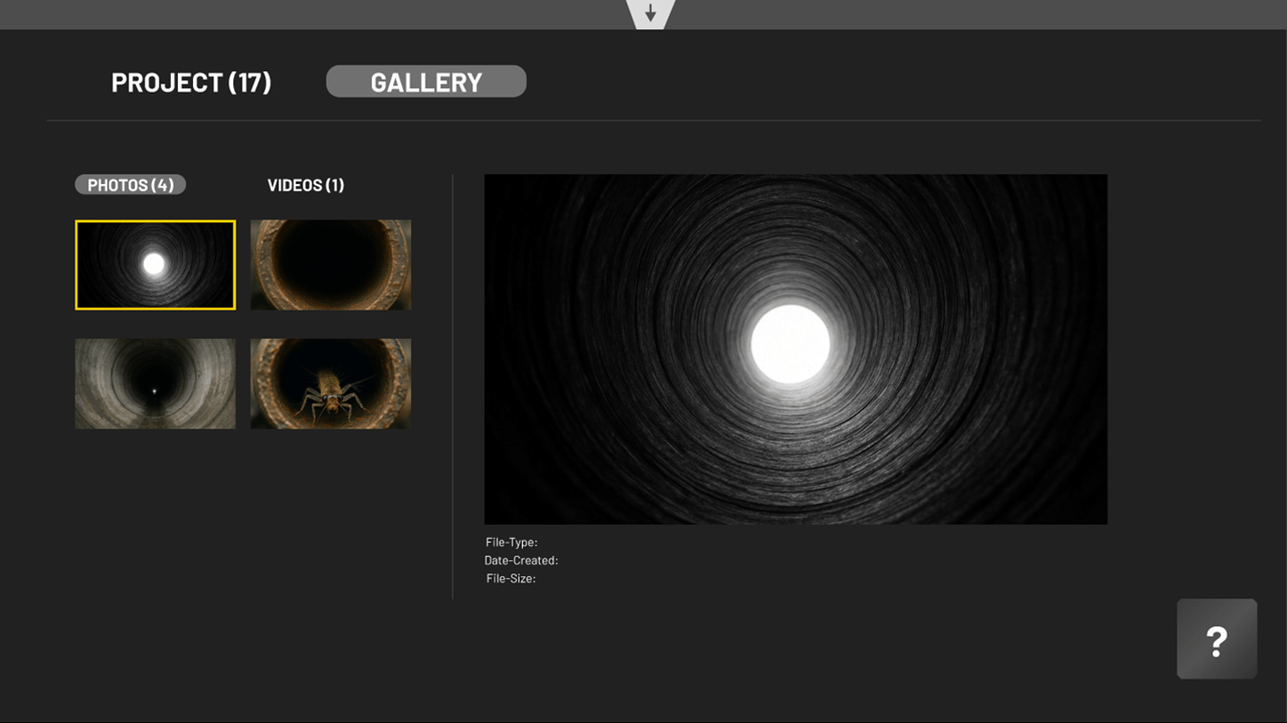

Project Management

The “Project Management” page provides an overview of all projects and allows users to create, view, edit, search, and delete projects, as well as access the gallery for unassigned media files.

Depending on the license, different functions are available here. Simple projects can always be created.

Gallery

Cleaning and Care

Crawler

- Remove dirt using clean water and a soft brush.

- Dry the device completely before storing it.

Camera head

- Clean the lens with a lint-free cloth and optical cleaning solution.

- Check the protective cover for cracks or scratches.

Cable Drum

- Always wind up the cable properly to prevent damage.

- Use a damp cloth to clean the drum mechanism.

Spare Parts and Repairs

If individual components are damaged or no longer function properly, please contact customer support.

Original spare parts are only available through authorized dealers.

Repairs may only be carried out by trained specialist personnel.

Defective components can be sent to the service center.

Contact for service requests:

NSP3CT.PRO GmbH

Am Galgenbichl 14

87509 Immenstadt

Tel.: +49 831 20530620

E-mail: service@nsp3ct.pro

Maintenance and Service

General maintenance instructions

To ensure long-term and reliable operation of the C-Series sewer inspection system, regular maintenance work is required. Please observe the following points:

- Clean the system after each inspection to prevent deposits and damage.

- Regularly check all electrical connections and cables for damage.

- Use only spare parts and lubricants recommended by the manufacturer.

Maintenance intervals

Component |

Maintenance Frequency |

Maintenance Measure |

Crawler |

After each inspection |

Clean the wheels and drives, perform a visual inspection for damage |

Camera system |

Weekly |

Clean the optics, check the seals |

Cable Drum |

Monthly |

Check for cable breaks, lubricate moving parts |

Control unit |

Quarterly |

Check for software updates, inspect buttons and ports |

Transportation

General information

The C-Series sewer inspection system consists of sensitive electronic and mechanical components. Therefore, special care is required during transport to prevent damage.

- Use the original transport cases or suitable protective packaging.

- Secure all components before transport to minimize vibrations and shocks.

- Make sure the system is dry and clean before it is packed.

Preparation of transport

Before transporting the system, the following steps should be carried out:

- Control unit: Switch off and disconnect all cable connections.

- Crawler: Clean and dry to prevent corrosion.

- Camera system: Attach the protective cover to protect the lens from scratches.

- Cable Drum: Fully wind up the cable and check for damage.

Transportation methods

| Type of transport | Requirements | Notes |

| Manual transport | Use the original case or a padded bag | Only suitable for short distances |

| Vehicle transport | Secure components on a non-slip surface | Avoid direct sunlight and high temperatures |

| Air/sea freight | Shock-resistant packaging, protected from moisture | Follow the transport guidelines of the airline or freight forwarder |

Means of transport

Selection of the means of transport: Choose a suitable means of transport that ensures the safe transport of the device. Make sure that the means of transport provides sufficient space and that the load can be securely fastened.

Securing the load: Secure the devices or the transport case firmly inside the means of transport. Use straps or other securing devices to prevent shifting or tipping over during transport.

For shipping by mail, ensure proper packaging. You are welcome to use the original packaging for this purpose.

During Transport

- Store the system on a stable and level surface.

- Avoid strong temperature fluctuations, as these can cause condensation.

- Keep the system away from aggressive chemicals or solvents.

Recommended environmental conditions

- Storage temperature: -20°C to +70°C

- Humidity: Max. 85%, non-condensing

- Protection from shocks: Padded storage recommended

After Transport

After transport, all components should be checked for damage:

- Visual inspection for cracks or deformation.

- Functional test of the control unit, the Crawler, and the camera.

- Check all cables and connectors.

If damage is found, the system must not be put into operation. In this case, contact technical support.

Troubleshooting

General information

If the C-Series sewer inspection system does not function properly, first check the most common causes using the table below.

- Turn the system off and on again to fix simple software errors.

- Check all cable connections for loose or damaged connectors.

- Perform a visual inspection for external damage to the Crawler, camera, and Cable Drum.

- If the problem persists, contact customer support.

Error diagnosis and solution

Problem |

Possible Cause |

Solution |

No image on the monitor |

Camera not connected or defective |

Check the connection, reconnect the camera |

Cable damaged or not properly connected |

Check the cable for damage, replace if necessary |

|

Software error |

Restart the software, check for updates if necessary |

|

Crawler does not move |

Activate drum freewheel |

Enable the function in the software |

Obstacle in the pipe |

Check the inspection path and remove the obstacle |

|

Cable blocked or twisted |

Untangle the cable, ensure correct routing |

|

Poor image quality |

Lens dirty |

Clean the camera |

Incorrect focus setting |

Adjust the focus in the software |

|

Insufficient lighting |

Increase the light intensity |

|

Cable Drum does not reel in/out |

Mechanical resistance in the drum |

Check the cable guide, lubricate if necessary |

Automatic retraction disabled |

Enable the function in the software |

|

Control unit not responding |

Software crashed |

Restart the software |

Connection to the Crawler interrupted |

Check system connections, restart if necessary |

|

Error message in the software |

Sensor data incorrect |

Restart the device, check for a software update |

Emergency measures

If the system fails during an inspection:

- Activate emergency stop: If there is a danger, activate the emergency stop function.

- Recover the trolley: If the trolley gets stuck, try carefully pulling it back using the cable reel.

- Restart the system: Switch off the entire system and then switch it back on after a few minutes.

- Use a backup system: If the fault cannot be rectified, use an alternative inspection unit.

- Contact support: If the problem persists, contact technical support.

Device take-back and disposal

Allgemeine Hinweise

1. Legal regulations

2. Environmentally sound disposal

3. Devices used purely for commercial purposes

Disclaimer

Garantiebedingungen

Scope

Warranty period

Guarantee services

- Repair or Replacement: During the warranty period, defective devices will be repaired or replaced at our discretion.

- Refund: If repair or replacement is not possible, we will refund the purchase price.

Exclusions

The following are excluded from the warranty:

- Damage caused by improper handling, installation, or use.

- Damage caused by external influences such as fire, water, or force majeure.

- Wear parts, such as batteries, that are subject to natural wear and tear.

Procedure in the event of a Warranty Claim

- Contact us: In case of a warranty claim, please contact our customer service department or your local service partner.

- Returns: Please return the defective device to us along with a return form including a detailed description of the fault.

- Processing: After receiving and inspecting the device, we will initiate the necessary steps to fulfill the warranty claim.

Legal Notice

Our operating instructions, manuals, and software are protected by copyright.

Copying, reproducing, translating, or converting them into any electronic medium or machine-readable form, in whole or in part, without the prior written consent of NSP3CT.PRO GmbH is prohibited.

Publisher:

NSP3CT.PRO GmbH

Am Galgenbichl 14

87509 Immenstadt im Allgäu

Germany